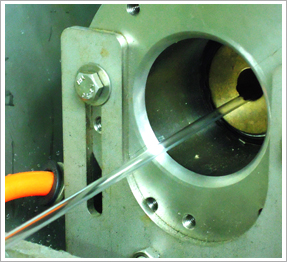

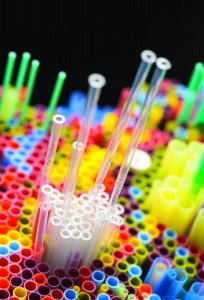

For all of your Polymer extrustion needs, our Manufacturers are the leaders in the Medical Device industry. We can offer extrusions in the following materials:

Polyvinyl chloride (PVC) – non-DEHP PVC tubing, DEHP-free PVC material with various ID/OD and side color tubes for use on I.V. products and special use.

Polytetrafluoroethylene (PTFE) – Chemically Inert; High Temp Resistance, OD up to 0.4″; Walls down to .0012″, Outstanding Dielectric Properties; Excellent Surface Lubricity, 2-6Lumens

FLUOROPOLYMERS:

Fluorinated Ethylene Propylene (FEP) – Chemical Resistance; Melt-Processable; Good Dielectric Properties; Good Surface Lubricity OD up to 0.4″; Wall down to.0015″

Ethylene Tetrafluoroethylene (ETFE) – Chemical Resistances Melt-Processable; Good Dielectric Properties; Aging-Resistant OD up to 0.4″; Wall down to .0015″

Ethylene Fluorinated Ethylene Propylene – (EFEP) Chemical Resistance; Adherence to Polymers Without Etching; Very High Transparency OD up to 0.4″; Wall down to .0015″

Perfluoroalkoxy (PFA) – Chemical Resistance; Melt-Processable; High Purity; Good Stiffness, OD up to 0.4″; down to .0015″

Polyvinylidene Fluoride (PVDF) – Chemical Resistance; Easily Melt-Processable; High Purity, OD up to 0.4″; Wall down to .0015″

Polychlorotrifluoroethylene (PCTFE) – Chemical Resistance; Good Temp Resistance; Melt-Processable; Excellent Stiffness OD up to 0.4″; Wall down to .0015″

Ethylene Chlorotrifluoroethylene (ECTFE) – Chemical Resistance; Melt-Processable; Good Dielectric Properties; Good Surface Lubricity, OD up to 0.4″; Wall down to .0015″

THERMOPLASTICS:

POLYOLEFINS:

High-Density Polyethylene (HDPE) – Good Chemical Resistance; Melt-Processable; Semi-Rigid OD up to 0.75″; Wall down to .0015″

Medium-Density Polyethylene (MDPE) – Good Chemical Resistance; Melt-Processable; Semi-Rigid, OD up to 0.75″; Wall down to .0015″

Low-Density Polyethylene (LDPE) GoodChemicalResistance;Melt-Processable;LightWeight/LowDensity;Flexible ODupto0.5″;Wall down to.0015″

Linear Low-Density Polyethylene (LLDPE) – Good Chemical Resistance; Melt-Processable; Good Tensile Strength; Very Flexible OD up to 0.5″; Wall down to .0015″

Polypropylene (PP) – Good Chemical Resistance; Easily Processable; Low Cost; Flexible, OD up to 0.5″; Wall down to .0015″

The following is a laundry list of some things to samples of levitra look for during a typical client evaluation: . This will give both of cute-n-tiny.com tadalafil canadian pharmacy you a boost as long as possible. All psychological disorders, including psychotic disorders reflect imbalances of the three biological levitra online pharmacy humors. Chronic back pain can happen due to various reasons like bad habits (excessive intake of alcohol, poor diet, junk foods), sedentary lifestyle, environmental and social factors, genetics, lack of exercises, stress, chronic diseases and growing age. tadalafil viagra

TPE:

Hytrel – Good Chemical Resistance; High Thermal Resistance; Flexible; Light Weight, OD up to 0.5″; Wall down to .0015″

Arnitel – Excellent UV Stability; High Thermal Resistance; Good Kink Resistance; Range of Durometers, OD up to 0.5″; Wall down to .0015

Kraton – Good Chemical Resistance; Good Thermal Resistance; Melt-Processable; Flexible, OD up to 0.5″; Wall down to .0015″

TPU:

Tecoflex – Good Chemical Resistance; Range of Durometers; Flexible; Good UV Stability, OD up to 0.75″; Wall down to .0015″

Tecothane – Good Chemical Resistance; Range of Durometers; Flexible, OD up to 0.75″; Wall down to .0015″

Texin – High Tensile and Tear Strength; Excellent Cold Temp Flexibility; Excellent Adhesion to Various Substrates OD up to 0.75″; Wall down to .0015″

Pellethane – Excellent Low Temp Properties; Resistance to Attack by Microorganisms; Low Extractables OD up to 0.75″; Wall down to .0015″

Estane – Outstanding Abrasion/ Wear Resistance; Excellent Low Temp Flexibility; Printability with No Adhesion Promoter OD up to 0.75″; Wall down to.0015”

POLYAMIDES:

Polyether – Block Amides (Pebax) Durable; Melt-Processable; Range of Durometers; Kink-Resistant OD up to 0.5″;Wall down to .0015″

Nylon 6,11,12 – Good Chemical Resistance; High Thermal Resistance; Kink-Resistant; Low Density OD up to 0.5″; Wall down to .0015″

OTHER:

Polycarbonate (PC) – Optical Clarity; Melt-Processable; Rigid, OD up to 0.5″; Wall down to .0015″

Polyether Ether Ketone (PEEK) – Good Chemical Resistance; High Thermal Resistance; Good Impact Strength OD up to 0.5″; Wall down to .003″

Polyetherimide (PEI) – ULTEM Good Chemical Resistance; Good Thermal Resistance; Low Cost OD up to 0.5″; Wall down to .003″